Product catalog

Feel free to send a message and we will help you find what you are looking for!

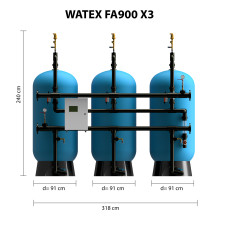

WATEX FA900x3 iron removal filter

WATER QUALITY PROBLEM

Iron and manganese are common elements found in groundwater that often cause major water quality issues. When water comes into contact with air, these metals oxidize, changing the water’s color and increasing its turbidity. Sediment forms, giving the water an unpleasant metallic taste. Over time, pipes and household systems may clog, and consumers receive discolored water.

The recommended concentration limits for drinking water are 0.1 mg/l for iron and 0.05 mg/l for manganese. When these values are exceeded, a specialized iron and manganese filtration system is required.

SOLUTION

The most effective solution to these problems is oxidation and sand filtration.

WATEX FA series filters are designed to remove turbidity, discoloration, iron, manganese, and unpleasant odors from water.

They are ideal for villages, towns, and industrial facilities, as well as for groundwater treatment and centralized water supply systems.

OPERATING PRINCIPLE

The FA filter operates on the principle of aeration and multi-layer filtration.

When water is aerated, iron and manganese oxidize and form solid particles, which are then removed by the filtration media.

Suspended solids and impurities are effectively captured and separated from the treated water.

Depending on the water quality and consumption, the filter must be periodically backwashed automatically or manually to restore its performance.

After each backwash, the filter media regenerates and continues normal operation.

Each unit is fully assembled and tested at the factory and requires only connection to water, power, and drainage to operate.

INSTALLATION AND CONNECTIONS

The system is equipped with two electric three-way valves that make operation simple and cost-efficient.

The piping is made of PVC pipes and fittings, with stainless steel connectors available upon request.

The filters can be backwashed in automatic or manual mode, depending on the setup and usage.

PRESSURE TANKS

The pressure filter tanks are made of fiberglass-reinforced material with an internal protective coating, capable of withstanding pressures up to PN10.

This construction ensures durability and long-term resistance to corrosion and aggressive water conditions.

FILTER MEDIA

For water purification, the system uses Aqua Mandix filtration media in combination with multi-layer quartz sand of various grain sizes (0.4–0.8 mm, 0.7–1.25 mm, 1–3 mm, 3–5 mm).

Aqua Mandix has a highly porous and active surface structure, allowing for efficient adsorption and accumulation of iron and manganese compounds.

Compared to other filtration materials, Aqua Mandix is lighter, more efficient, and requires less rinse water, which reduces operational costs.

CONTROL SYSTEM

The system features an automatic control module with an LCD display, allowing the operator to set and monitor parameters such as date, time, and regeneration cycles.

It is protected against unauthorized access and can be integrated with SCADA or GSM remote monitoring systems.

The backwash cycle is initiated either by elapsed time or by the measured water volume.

The system can also be connected to an air pump or compressor if required.

AIR SUPPLY SYSTEM

Aeration (oxidation) is achieved using an oil-free air compressor.

The system is compatible with all major compressor brands and includes an integrated air control unit.

The air control system features a built-in flow switch that sends a signal to open the solenoid valve when water begins to flow.

Air is injected into the water before filtration to initiate the oxidation of iron and manganese.

SYSTEM MAINTENANCE

The system operates without the need for chemical additives. Maintenance consists of ensuring proper air supply and regular backwashing of the filters. When operated according to the manufacturer’s recommendations, the filters provide consistently high water quality. Thanks to the automatic control system, the filtration unit is energy-efficient, reliable, and suitable for continuous year-round operation.

Technical parameters of equipment | Unit | Model |

WATEX FA900x3 | ||

Flow rate * Qnom | m3/h | 15.6 |

Flow rate ** Qmax | m3/h | 23.4 |

Total amount of water for each backwash *** | m3 | 2.60 |

Minimum flow rate for rinsing | m3/h | 19.5 |

Tank size (diameter) | inches | 36 |

m | 0.91 | |

Tank volume | liters | 1000 |

Total amount of filter media | liters | 667 |

Dimensions of equipment | ||

Length | m | 3.18 |

Width | m | 1.21 |

Height | m | 2.40 |

Filtration | Iron, Manganese, Turbidity, Odor, Color | |

Tank material | FRP (Fiberglass Reinforced Plastic) | |

Filter media | Aqua Mandix, Quartz sand 0.7x1.2mm, 3x5 mm | |

Connection. in /out/ drain | mm | D75 |

Piping material | PVC | |

Valve type and drive | BELIMO three-way electric valves | |

Operating pressure | bar | 2-6 |

Electric Connection | 220V, 50Hz, 1 phase | |

Electricity consumption | W | 3 W |

* Filtration speed 8 m/h

** Filtration speed 12 m/h

*** Backwash 8 min

| Width (cm) | Height (cm) | Length (cm) | Weight (kg) |

|---|---|---|---|

| 0 | 0 | 0 | 1 |

Available on order

Available on order

Delivery time: 2-5 working days

Delivery time: 2-5 working days

This is a good choice!

This is a good choice!